In simple terms, ALL composite products, which are usually manufactured using a matrix of resins (polymer) & fabrics (fibers), are considered to be FRP (Fiber-Reinforced-Plastic or Polymer). This includes fiberglass, carbon, and Kevlar (aramid) made products.

They are considered to be “thermosets,” meaning, as the product fully cures and hardens through thermo (heat) reaction, the shape of the products are “set.” They cannot be “re-heated” to reform or reshape. This is an opposite characteristic of “thermoform” products, such as polyurethane, where the materials can be re-heated to re-form its shape.

Because of what we believe to be somewhat deceiving marketing tactics of companies within the after-market aero industry, most consumers and even avid enthusiasts have been successfully led to believe that FRP products and fiberglass products are two different types of material. Fiberglass made products have left a bad taste over the years and certain companies will make a serious effort to distinguish fiberglass and FRP (or create some other fancy name) when they are, in fact, the same thing.

A company can call their fiberglass-made product “FRP,” however when asked if FRP is fiberglass, they can truthfully say “not really“, because FRP is a general categorization for all composite parts. Is a fruit an apple? Not really. Is an apple a fruit? Yes. We hope this makes sense because this technicality has really led to confusion amongst consumers.

Just to clarify and just for the record, Shine Auto Project is stating that all fiberglass made products are considered FRP. FRP is simply a general categorization for fiberglass, carbon (CFRP), and Kevlar made products.

Fiberglass = FRP (They are, in fact, the same thing. Some topics are debatable… this is not one of them)

Having said that, fiberglass products are not “bad” products. Generally, fiberglass products have their pros and cons and it really all depends on application. From experience, they are fine for spoilers, wings, hoods, and fenders, but are not ideal for bumpers or any part which sits close to the ground because of brittleness and limited flexibility for fitting ease and absorbing impact from daily mishaps.

Just like everything else, not all manufacturers produce products the same way or at least with equal quality as composite products are generally hand-crafted and human error is always of concern. There are well made fiberglass products just as there are poorly made fiberglass products. Over the past decade, aero after-market companies have flooded the market with sub par fiberglass products, ultimately leaving the consumer with a bad taste forcing companies to re-invent the “image” of their products. Once again, fiberglass products are not bad products. It’s the skill and philosophy of the manufacturer that should be judged.

» Keeps shape once fully cured

» Hard and firm for applications seeking those characteristics

» Easy for body shops/customizers to add, change, or manipulate shape

» If quality part, easier to paint versus urethane after-market aero parts that have surface adhering issues

» Can be made light-weight if within skill of manufacturer.

» Repairable

» Long lasting with proper care. No rust and no warpage (if made or cured properly)

» Generally limited in flexibility and brittle

» Prone to cracking or disintegrating upon minor to heavy impact

» If made improperly or poor fitting, because FRP products are “thermosets” and shape cannot be re-heated, a shop will have to manipulate shape by shaving, adding, and worse case… chopping, adding, and pasting together. This is the main reason to avoid poorly made FRP products

Through careful selection of resins, surface coats, and fabrics, Shine has been able to develop a proprietary flexible fiberglass (FRP) formula. Our products behave very similar to oem bumpers (roughly 75% of oem flexibility), however, is still worked with and prepared to paint like general fiberglass products. We have essentially eliminated some of the cons of FRP products creating the ideal material of choice for the after-market aero enthusiast.

The Shine Hybrid FRP product is heavily inspired by Ings+1’s (a popular Japanese aero parts manufacturer) “Hybrid Aero” FRP products, hence given a similar name. What had caught our attention was the unfathomable flexibility of their fiberglass (FRP) aero products, since it was generally known (and still is) for fiberglass products to be stiff and brittle. Flexibility, hence durability, has always been a highly sought after characteristic/benefit consumers have needed in search of after-market exterior aero components. Particularly, bumpers, lips, and side skirts.

Shine has invested years of research and experimentations to offer an ideal product that meets and exceeds the demands and expectations of enthusiasts looking for after-market aero components. We believe Shine’s current Hybrid FRP offering is at least equal to if not better than our initial inspiration for the formula. It is a very special, unique, and evolving formula that has taken tons of experimentations, tons of feedback from body shops, and tons of feedback from customers, to perfect. We are very confident in our formula and there are numerous satisfied customers across the globe who are enjoying the benefit our product offers.

After-market aero companies who are struggling to re-invent themselves after flooding the market with sub par fiberglass products for many years, are eager to rename their products “X (insert word or letter associated with durability/flexibility)” FRP. Any company can call or portray their products however they wish, but the truth of the matter is, not all manufacturers and their products are equal. A flexible fiberglass formula cannot be had overnight. As mentioned above, it takes years of research, experimentation, and feedback to create an ideal formula. It is very difficult to create such a formula and it is questionable if some of these companies have developed the formula or just simply renaming the same standard and sub-par fiberglass products they’ve been offering for years. Be weary and please do your research before purchasing. A good place to start is to look at testimonials and feedback on specific automotive forums for specific products (one good product from a manufacturer, does not necessarily equate to every product from the manufacturer being good.)

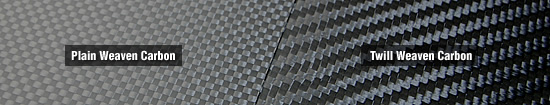

Click here to visit our blog on the differences between Plain and Twill weave carbon.

» We use grade A UV protected marine gel coat as the primary surface coat. For those looking to add automotive clear coat for added weather protection and increased gloss, the surface coat can be sanded (600 or 800 grit wet) for application.

Our Carbon Fiber fabric is sourced from a world renown producer, Toray Industries Japan. Toray Carbon is used by high-end auto manufacturers such as Ferrari and Mercedes-Benz. We have used other high-end brands such as Hexcel in the past, however, we have found Toray Carbon to be a superior quality Carbon Fiber. Most carbon, in particular, inexpensive brands from Chinese or Taiwanese producers have shown to have aesthetic flaws upon close observation. One of the major flaws is a wavy ocean-like surface reflection. It will appear as though the carbon is not fully pressed to the surface. Other flaws such as carbon strand gaps and random lines from carbon separation start to appear. For visual aesthetic purposes, we wish to stay away from these sub-par carbon producers and solely stick with Toray Carbon. Carbon parts are not equal in quality and for the most part, the pricing of such parts reflect their quality.

» 5.07oz 2×2 3k Twill Weave Carbon Fiber

» 5.07oz 3k Plain Weave Carbon Fiber (also sometimes mistakenly referred to as 1×1 Weave)

The differences between the two are primarily aesthetic and it is really only a matter of preference when you decide on which to choose for your carbon fiber part. Because of the tighter plain weave pattern, plain weave tends to reflect less light resulting in a darker overall look compared to twill weave. Image below demonstrates visual difference.

Our general carbon fiber parts are hand-crafted using a “wet lay-up’ technique. A majority of carbon fiber parts are made using this technique as it is an industry wide standard. However, as all hand made things, quality is determined by crafter as well as the surface coat used, fabric quality, and resin used. Once again, it is the skills and philosophy of the manufacturer that should be judged as not all carbon parts are equal.

Carbon Kevlar is a matrix of carbon fiber strands and Kevlar strands for slightly increased thickness and added strength as Kevlar is ultimately a stronger material than Carbon fiber. The black carbon fiber strands mixed with yellow Kevlar strands give the part a greenish-yellowish hue from a distance.

We are one of the few companies in the industry willing to offer parts we generally make in carbon to be made in Carbon Kevlar — in both plain and twill weave patterns. We’re looking to distinguish ourselves from our competitors by focusing on the needs of the enthusiasts and help them build unique setups to add variety to the automotive community.